Fire Protection Engineering Laboratories and Associated Equipment

In addition to shared laboratory spaces, dedicated laboratory facilities are available to provide instructional support for the FSET program.

The Fire and Safety Engineering program at UNC Charlotte provides a unique laboratory with equipment for both undergraduate and graduate students in the Fire and Safety Engineering program who desire to work on a range of projects in the field of fire protection engineering. The laboratory is located in Room 315 of Smith Building and is facilitated with state-of-the-art apparatuses and equipment that enable fulfilling research projects in different areas including Explosion, Flammability and Toxicity, Fire dynamic, and Structure Fires. Below you will find a list of testing apparatuses and equipment and their specifications:

Cone Calorimeter

The laboratory uses a brand-new cone calorimeter for evaluating any material’s flammability and smoke generation. This is a widely used technique in the field of fire protection engineering through oxygen consumption calorimetry theory. The apparatus was developed by Fire Research Division at National Institute of Standard and Technology (NIST) in 1982, and it became a recognized standard bench scale test listed in many standard protocols including ASTM E1354, ISO 5660-1, D5485, and NFPA 271. The Cone Calorimeter consists of a conical radiant heat source to expose materials to heats that are representative of radiation during different fire scenarios. The test provides various measurements such as time to ignition, amount of heat released by burning of materials, mass loss rate, and smoke generation, which are important flammability properties used to characterize fire severity, fire growth and its role in igniting other materials, and its contribution to smoke generation and toxicity.

Fourier Transform Infrared Spectroscopy (FTIR)

The FTIR spectrometer is a state-of-the-art technique used to evaluate constituents of gas emission by fires. The apparatus offers a vast range of analytical opportunities for research in academia and forensic tests. FTIR uses infrared spectroscopy to measure absorption of infrared radiation by solids, liquids and gases across a range of spectrum wavelengths. The infrared absorption spectra are based on the molecular structures present in each component, which provides a detailed analysis and the identities of any substance components. The application of FTIR spectroscopy helps fire protection engineers to evaluate toxicity of gases in smoke generated by any burning material or fire event. The FTIR system available in the Fire Protection Engineering laboratory at UNC Charlotte facilitate measures 20 different toxic gases in smokes including H2O, CO2, CO, Nitrous Oxide N2O, Nitrogen Monoxide NO, Nitrogen Dioxide NO2, Sulfur Dioxide SO2, Ammonia NH3, Hydrogen Chloride HCL, Hydrogen Fluoride HF, Methane CH4, Ethane C2H6, Ethylene C2H4, Propane C3H8, Hexane C6H14, Formaldehyde CH2O, Hydrogen Cyanide HCN, Hydrogen Bromide HBr, Acrolein C3H4, Phenol C6H6O, and NOx.

NBS Smoke Density Chamber

The Smoke Density Chamber provides an opportunity for standard tests on smoke generated by the combustion of solid materials. The apparatus was developed by National Bureau of Standard (Now it is known as National Institute of Standard and Technology (NIST)) and listed in various standard test protocols including ASTM E 662, ASTM F 814, NFPA 258, ISO 5659, IMO FTPC Part 2, ATS 1000.001, and NES 711. This widely used test instrument measures the specific optical density of a flat specimen of up to 25 mm thick mounted in both vertical and horizontal orientations. The chamber has vertical and horizontal heaters that can be set to radiant heat flux ranging from 5 to 100 kW/m2. The Smoke Density Chamber is connected to the lab FTIR spectrometer for smoke components measurement, and it can be used for both service industry and research projects.

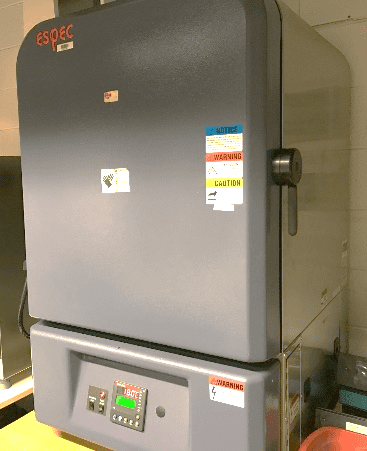

Environmental Test Chamber

The Fire Protection Engineering Laboratory has a unique Environmental test chamber manufactured by ESPEC. The chamber enables conditioning of any materials at a certain temperature and humidity before tests. The instrument has a capability of programming different environmental conditions and remote controlling the chamber condition with a size of 206 liters. Temperatures inside the chamber can be set in the range of -20 to 85 °C (-4 to 185 °F) and relative humidity in the range of 10% to 95%. The chamber is useful for many service industry and research projects, especially when sample temperature and humidity prior to test is important, such as with forest fuels.

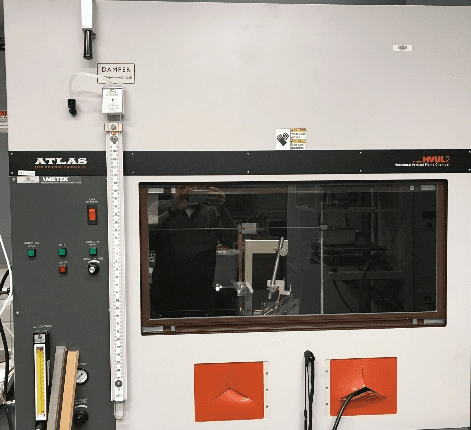

UL-94 Flammability Chamber

The UL-94 flammability chamber is a well-known standard test in the field of fire protection engineering. The chamber consists of a specimen holder which has adjustable horizontal and vertical specimen support and a burner that are mounted inside a chamber with an inside volume of 1.0 m3. The burner is in compliance with ASTM D 5025, and samples can be exposed to the burner in 0°, 25° and 45° orientation. There are two access ports enabling easy entry to the chamber for movement of the burner and specimen. This is an apparatus for standard tests listed as UL-94, ISO 1210, ISO 9770, ISO 9772, ISO 9773 and IEC 60695. For more information please see UL-94 documentation.

Simultaneous Thermal Gravimetric Analysis (TGA)/Differential Scanning Calorimetry (DSC)

The Q600 thermal analysis machine is manufactured by SDT Technology and provides simultaneous measurement of weight change (TGA) and true differential heat flow (DSC) on the same sample from ambient temperature to 1500 °C. It features a field-proven horizontal dual beam design with automatic beam growth compensation, and the ability to analyze two TGA samples simultaneously. DSC heat flow data is dynamically normalized using the instantaneous sample weight at any given temperature. The sample capacity is 200 mg, and the sensitivity of the balance is 0.1 µg. The accuracy of measurement is noted as ±2% based on manufacturer.

Furnace and Oven

The Fire Protection Engineering Laboratory has various ovens and furnaces for both research and service industry projects. The laboratory has two Isotemp Fisher Scientific ovens that provide a testing temperature range of 50°C- 250°C. The oven has automatic features for programming of constant and transient temperature. There is also a ceramic furnace for higher temperatures up to 1100 °C (2012 °F), which can accommodate samples with a size of 12.7 cm Width, 10.8 cm Height and 15.2 cm Depth and a maximum weight of 10 kg.

FLIR Thermal Infrared High Speed Camera

This state-of-the-art infrared high-speed camera manufactured by FLIR is capable of recording with a resolution of 1.3 Million Pixel. The camera has an integration time capability in the range of 480 ns to 687 s and a temperature range of -20°C to 650 °C (-4 °F to 1202 °F). It also has a spectral range of 7.5-10.5 µm and is capable of recording fast motion thermal phenomena with frame rate of up to 4000 Hz. Various lenses come with the camera which make a unique opportunity to monitor any fire dynamic and explosion phenomena.

PHOTRON High Speed Camera

The laboratory has a high-speed camera (FASTCAM Mini UX) manufactured by PHOTRON for evaluation of any phenomena in slow motion. The camera has a 1.3 megapixel image resolution (1280×1024 pixels) with frame rates up to 2000 frames per second and can capture video up to maximum frame rate of 102,400 fps (image resolution of 1280 × 24 pixels) with 32 GB memory. Accessories that come with the camera include a tripod to fix the camera, a trigger to remotely start recording and various zoom lenses for different applications. The camera has also a tugged design with a compact camera body (weighting just 1.5 kg), suitable for operation in high shock and vibration environments.

High-End Radiation Thermometer (Pyrometer)

The high-end radiation thermometer manufactured by Heitronics is a unique camera for radiation measurement of different objects from remote distances. The device works in spectral response 8-14 µm and it can measure temperature from -100 °C to 3000 °C. The camera comes with accessories including lenses with various zoom capacities and it has its own built-in software for recording and monitoring experiment data.

Explosion Chamber

The laboratory employs a built-in rectangular combustion chamber for explosion testing. The chamber made of thick acrylic sheets has a capacity of 0.21 m3 (0.45 m Height, 0.48 m Width and 1 m Length). The combustion chamber is equipped with an igniter and a port to inject gas into the chamber which is monitored by a gas mass flow meter. It is also facilitated with thermocouples and pressure probes to measure overpressure and temperature during the test. The chamber is fully transparent for monitoring flame propagation from any side.

Bench Scale Gas Burners and Pool Fires

Gas burners and pool fire pans of various shapes and sizes for bench scale tests are available in the Fire Protection Engineering Laboratory including square and rectangular gas burners, and various pool fire pans of circular and square shapes. Please contact jhashemp@uncc.edu for further information about sizes of burners and pool fire pans.

In addition to the above equipment and test machines, the laboratory is also facilitated with many other sensors and equipment listed as follows:

-

AC/DC Power Supply 3Amp/30V

-

Pressure Transducers ( Low range, High range and Differential Pressure)

-

Array of Pitot Tubes

-

Fluke Blackbody Infrared Calibrator

-

In-House Developed Digital Particle Image Velocimetry (DPIV) – up to 30 Hz.

-

2 × National Instatements DAQ chassis and 12 × Modules

-

8 × Gordon and Schmidt-Boelter Heat Flux Gauges

-

Various Types of Thermocouples

-

Fluke 971 Temperature /Humidity Meter (5-95%)

-

Fluke Metrology Well ( Model 9144- Temp: 50-660 °C)

-

EXTECH Temperature/Humidity Meter (5-95%)

-

Gas Mass Flow Meters

-

Hot Wire and Cup Anemometers

-

Displacement Gauge

-

Low and Medium range Scales

Outdoor Fire Facility

Fire and Safety Engineering program collaborates with the College of Engineering and Technology at Western Carolina University for outdoor fire testing at Green Energy Park in Jackson County, North Carolina. The facility includes a wide outdoor space for general fire testing (Pool fires, Forest Fires and Structure fires). Various equipment including cylindrical radiation chamber, several industrial scales and large air blowers are available on site.

Should you have any question about the above information or need more detail, please contact Dr. Javad Hashempour through email to jhashemp@charlotte.edu or phone number of 704-687-5065.